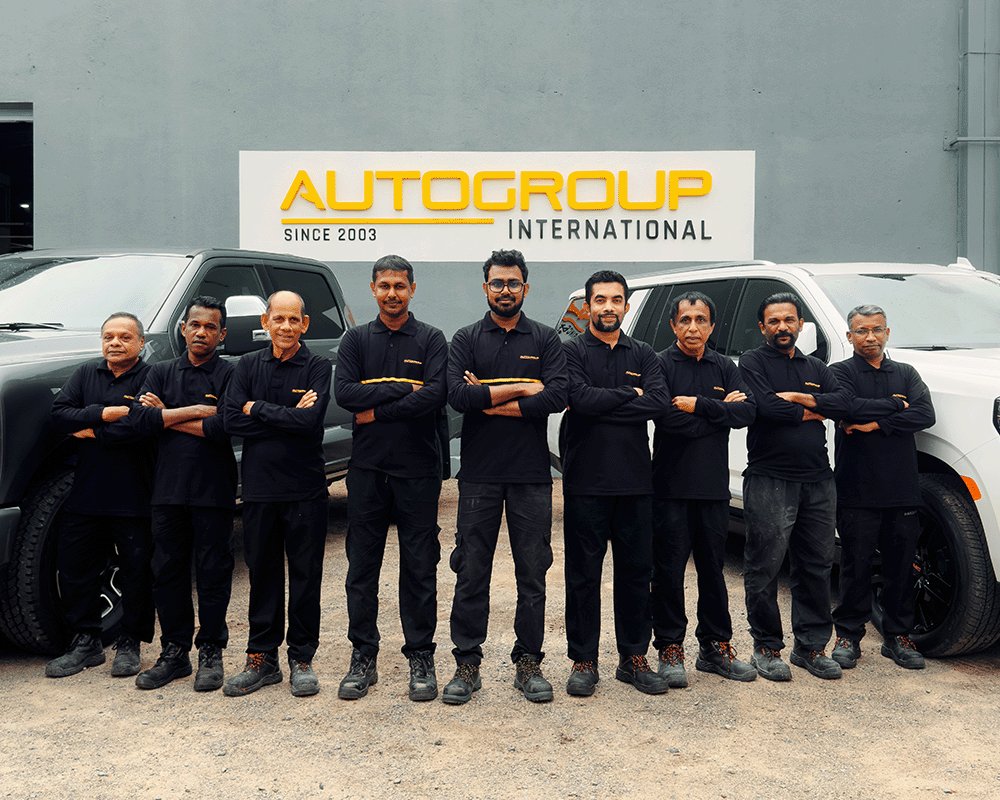

The Backbone of our Conversion Process

The backbone of Autogroup International's conversion process lies in its team of skilled engineers. These engineers are divided into different specializations, each handling specific aspects of the conversion process. The team includes mechanical engineers, electrical engineers, plastics engineers, and experts in reverse engineering. Together, they work collaboratively to tackle the various challenges involved in converting a vehicle from Left-hand drive to Right-hand drive.

The Key to Conversion Success

Mechanical engineering plays a crucial role in the conversion process. The mechanical engineering team at Autogroup International is responsible for handling modifications related to the steering system, brake system, dashboard, HVAC units, and other mechanical components. The engineers meticulously examine each vehicle, identifying the necessary modifications and designing solutions that ensure optimal performance and safety. They take into account factors such as ergonomic design, materials, metallurgy, and manufacturing processes to achieve the desired outcome.

Powering the Conversion

Electrical engineering is another vital aspect of vehicle conversions. Autogroup International's electrical engineering team is responsible for modifying and reengineering electrical components such as wiring looms, exterior lighting, airbags, seating controls, door switch panels, and ECM reprogramming. They ensure that all electrical modifications comply with safety standards and that the vehicle's electrical systems function seamlessly within the RHD orientation.

Precision in Component Manufacturing

Plastics engineering plays a significant role in the conversion process, particularly in the manufacturing of modified components. Autogroup International's plastics engineering team selects suitable plastic materials, conducts research and sample testing, and oversees the production of components such as dashboard panels, HVAC units, door switch panels, and other plastic parts. Their expertise ensures that all components meet OEM standards and are manufactured to the highest quality.

Ensuring Compliance and Traceability

The engineering documentation team at Autogroup International plays a critical role in documenting and ensuring compliance with homologation and design rules for government regulations in the United Kingdom, Australia, South Africa, Indonesia, Malaysia, and forty other right-hand drive countries. They maintain control over engineering-related documents and records, establishing traceability and accountability for each vehicle conversion, modification, and component. This meticulous documentation process ensures that all conversions meet the necessary standards and requirements.

Consistency and Quality Assurance

Conformity of Production (COP) is a vital phase in the engineering process, ensuring that every part manufactured for the conversion meets the necessary design requirements. Autogroup International's engineering team follows COP standards to guarantee the consistency, size, and design of all converted components. This meticulous approach allows for easy sourcing of parts and ensures that the final product meets the highest quality standards.

More about...

Conversion

Converting a vehicle from left-hand drive (LHD) to right-hand drive (RHD) is a complex and meticulous process.

Learn more

Our Heritage

In 1993 in Australia, an automotive revolution was started which would go on to transform the global automotive landscape.

Learn More

Manufacturing

We take great pride in our ISO 9001:2015 Quality Assurance Manufacturing of components necessary for conversion.

Learn more

Safety & Compliance

We exceed ISO 9001:2015 Quality Assurance standards, with over 1600 inspection criteria for every vehicle we convert.

Learn more